Before proceeding to Chapter 3, some terms and equations commonly used in reaction engineering need to be defined. We also consider the special case of the plug-flow design equation when the volumetric flow rate is constant.

2.6.1 Space Time

The space time tau, τ, is obtained by dividing the reactor volume by the volumetric flow rate entering the reactor

τ is an important quantity!

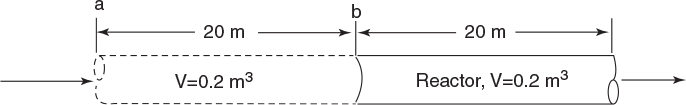

The space time is the time necessary to process one reactor volume of fluid based on entrance conditions. For example, consider the tubular reactor shown in Figure 2-12, which is 20 m long and 0.2 m3 in volume. The dashed line in Figure 2-12 represents 0.2 m3 of fluid directly upstream of the reactor. The time it takes for this upstream fluid volume to enter the reactor completely is called the space time tau. It is also called the holding time or mean residence time.

Space time or mean residence time

τ = V/υ0

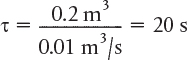

For example, if the reactor volume is 0.2 m3 and the inlet volumetric flow rate is 0.01 m3/s, it would take the upstream equivalent reactor volume (V = 0.2 m3), shown by the dashed lines, a time τ equal to

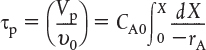

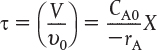

to enter the reactor (V = 0.2 m3). In other words, it would take 20 s for the fluid molecules at point a to move to point b, which corresponds to a space time of 20 s. We can substitute for FA0 = υ0CA0 in Equations (2-13) and (2-16) and then divide both sides by υ0 to write our mole balance in the following forms:

For a PFR

and

For a CSTR

For plug flow, the space time is equal to the mean residence time in the reactor, tm (see Web PDF Chapter 16). This time is the average time that the molecules spend in the reactor. A range of typical processing times in terms of the space time (residence time) for industrial reactors is shown in Table 2-4.

TABLE 2-4 TYPICAL SPACE TIME FOR INDUSTRIAL REACTORS2

| Reactor Type | Mean Residence Time Range | Production Capacity |

| Batch | 15 min to 20 h | Few kg/day to 100,000 tons/year |

| CSTR | 10 min to 4 h | 10 to 3,000,000 tons/year |

| Tubular | 0.5 s to 1 h | 50 to 5,000,000 tons/year |

2 Trambouze, Landeghem, and Wauquier, Chemical Reactors (Paris: Editions Technip, 1988; Houston: Gulf Publishing Company, 1988), p. 154.

Practical guidelines

Table 2-5 shows an order of magnitude of the space times for six industrial reactions and associated reactors.

TABLE 2-5 SAMPLE INDUSTRIAL SPACE TIMES3

| Reaction | Reactor | Temperature | Pressure atm | Space Time | |

| (1) | C2H6 → C2H4 + H2 | PTR† | 860°C | 2 | 1s |

| (2) | CH3CH2OH + HCH3COOH → CH3CH2COOCH3 + H2O | CSTR | 100°C | 1 | 2h |

| (3) | Catalytic cracking | PBR | 490°C | 20 | 1 s < τ < 400 s |

| (4) | C6H5CH2CH3 → C6H5CH = CH2 + H2 | PBR | 600°C | 1 | 0.2 s |

| (5) | CO + H2O → CO2 + H2 | PBR | 300°C | 26 | 4.5 s |

| (6) | C6H6 + HNO3 → C6H5NO2 + H2O | CSTR | 50°C | 1 | 20 min |

† The reactor is tubular but the flow may or may not be ideal plug flow.

3 Walas, S. M. Chemical Reactor Data, Chemical Engineering, 79 (October 14, 1985).

Typical industrial reaction space times

Table 2-6 gives typical sizes for batch and CSTR reactors (along with the comparable size of a familiar object) and the costs associated with those sizes. All reactors are glass lined and the prices include heating/cooling jacket, motor, mixer, and baffles. The reactors can be operated at temperatures between 20 and 450°F, and at pressures up to 100 psi.

TABLE 2-6 REPRESENTATIVE PFAUDLER CSTR/BATCH REACTOR SIZES AND PRICES†

| Volume | Price |

| 20 dm3 (Waste Basket) | $30,000 |

| 200 dm3 (Garbage Can) | $40,000 |

| 2,000 dm3 (Jacuzzi) | $75,000 |

| 30,000 dm3 (Gasoline Tanker) | $300,000 |

† Doesn’t include instrumentation costs.

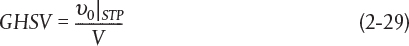

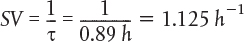

2.6.2 Space Velocity

The space velocity (SV), which is defined as

might be regarded at first sight as the reciprocal of the space time. However, there can be a difference in the two quantities’ definitions. For the space time, the entering volumetric flow rate is measured at the entrance conditions, but for the space velocity, other conditions are often used. The two space velocities commonly used in industry are the liquid-hourly and gas-hourly space velocities, LHSV and GHSV, respectively. The entering volumetric flow rate, υ0, in the LHSV is frequently measured as that of a liquid feed rate at 60°F or 75°F, even though the feed to the reactor may be a vapor at some higher temperature. Strange but true. The gas volumetric flow rate, υ0, in the GHSV is normally reported at standard temperature and pressure (STP).

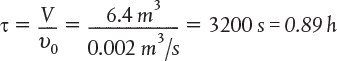

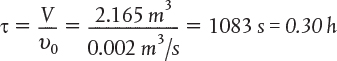

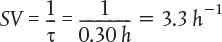

Example 2-6 Reactor Space Times and Space Velocities

Calculate the space time, τ, and space velocities for the reactor in Examples 2-1 and 2-3 for an entering volumetric flow rate of 2 dm3/s.

Solution

The entering volumetric flow rate is 2 dm3/s (0.002 m3/s).

From Example 2-1, the CSTR volume was 6.4 m3 and the corresponding space time, τ, and space velocity, SV are

It takes 0.89 hours to put 6.4 m3 into the reactor.

From Example 2-3, the PFR volume was 2.165 m3, and the corresponding space time and space velocity are

Analysis: This example gives an important industrial concept. These space times are the times for each of the reactors to take the volume of fluid equivalent to one reactor volume and put it into the reactor.

Leave a Reply